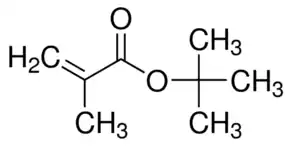

t-BMA

Tertiary Butyl Methacrylate

t-BMA (tert-Butyl Methacrylate) offers several notable advantages for polymer manufacturers. Firstly, TBMA has a high glass transition temperature (Tg) of 107°C, significantly higher than other methacrylates. This elevated Tg is due to the presence of the t-butyl group, providing enhanced thermal stability. Secondly, TBMA has a solubility parameter (SP value) ranging from 8.0 to 8.5, which is lower than that of PMMA (SP value = 9.3 to 9.45). This lower SP value indicates that TBMA can dissolve in a broader range of solvents, offering more flexibility in formulation.

Furthermore, TBMA enables the production of polymers with lower viscosity compared to PMMA, making it advantageous for high-solids formulations. This characteristic is particularly beneficial in applications where reduced viscosity is essential for processing and application efficiency. Lastly, TBMA exhibits resistance to transesterification reactions, making it an effective protective group in polymer synthesis. For instance, when creating a copolymer of MMA/TBMA and subjecting it to transesterification, only the MMA units will undergo modification while the TBMA units remain unchanged. This selective transesterification capability allows for precise control over polymer properties.

Overall, TBMA’s high thermal stability, versatile solubility, low viscosity, and resistance to transesterification make it a valuable monomer for polymer manufacturers looking to enhance their product offerings.

MADE IN JAPAN

Properties

| Purity | 98%min |

|---|---|

| Water | 0.1%max |

| Color | APHA 20max |

Chemicals

Chemical Structure

Identifiers

CAS#: 585-07-9

Function

- Heat Resistance

- Hydrophobic

- Adhesion

- Chemical Resistance

- Scratch Resistance

- Weatherability

Application

- Adhesives

- Industrial Coatings